Gasket Seal ORing Rebuild Kit For Pentair Pac Fab Challenger, High Flow, High PSI, Waterfall, Pinnacle Pool Pump Repair Kit 73 This kit is compatible with all Challenger pool pump models This includes both the round style and square style housing orings (You will only need one of them depending on your pump model)Challenger Disaster questions for Oring experts Discussion I've read quite a bit of technical stuff on the Challenger Disaster and the Orings, but there's still a few things I am trying to understand better about Orings in particular, since I've never designed something that uses them or had to figure out why they're not working as desiredAn Oring, also known as a packing or a toric joint, is a mechanical gasket in the shape of a torus;

2

O ring seal challenger

O ring seal challenger-The chemistry behind the Challenger Disaster Polymer chemistryI am unsure as to how the elasticity and plasticity of the Viton selected in this application changed as it approached its lower operating temperature From personal experience, many plastics tend to become quite stiff long before they reach their

Wholesale Bearing Seal Definition Manufacturer And Supplier Factory Gs Seal

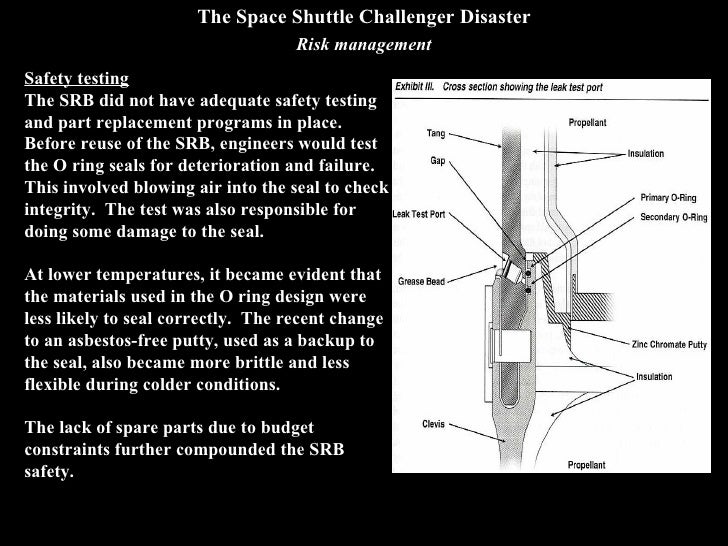

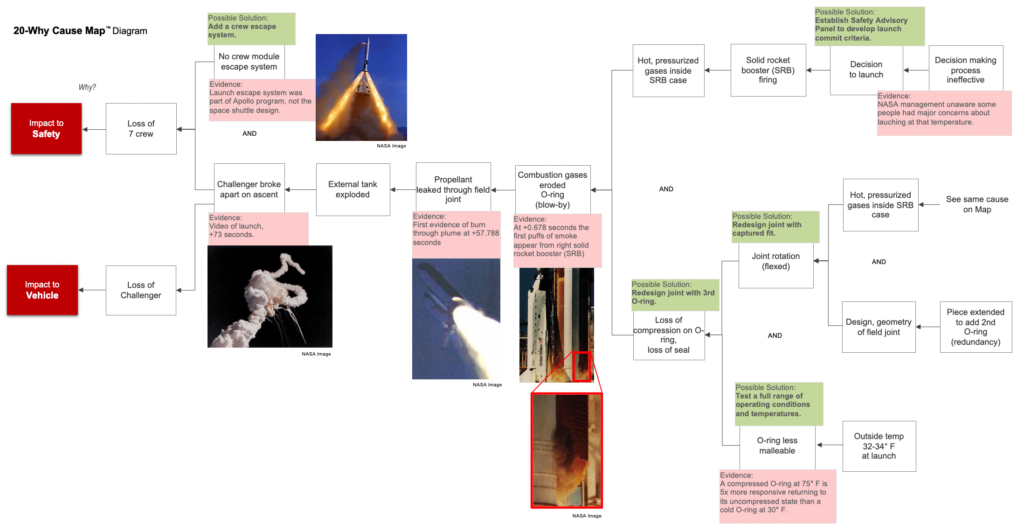

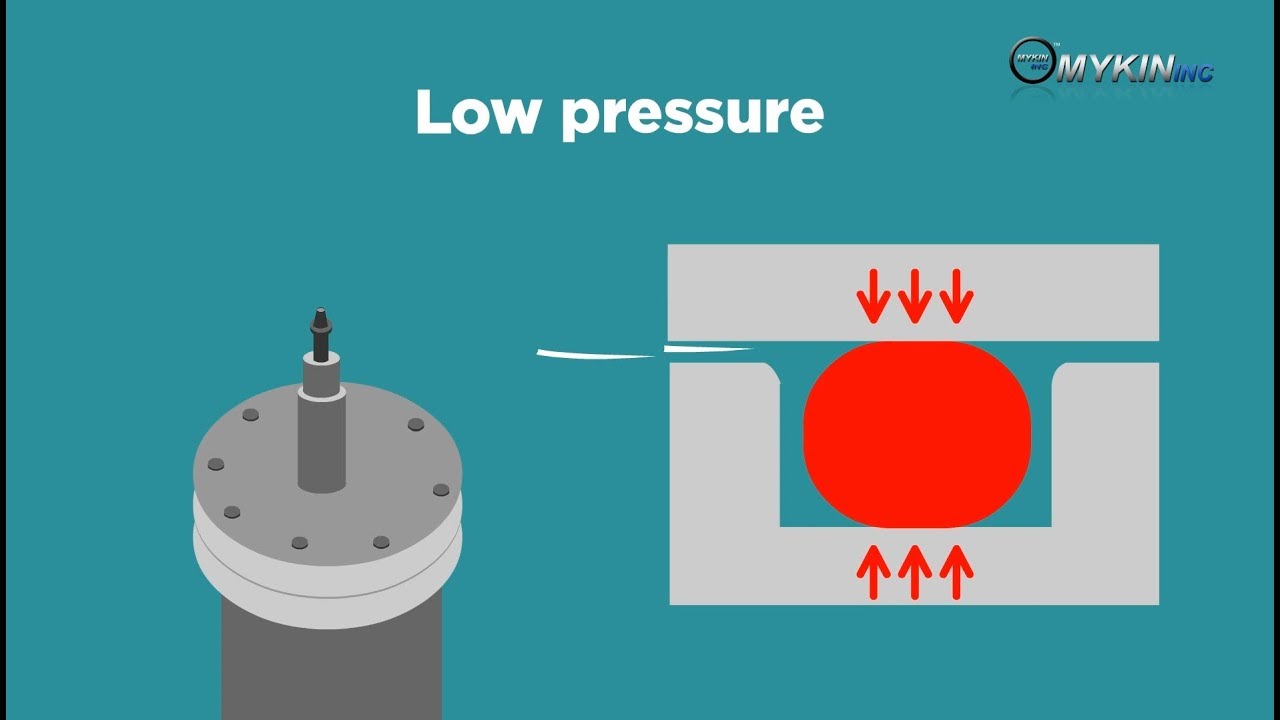

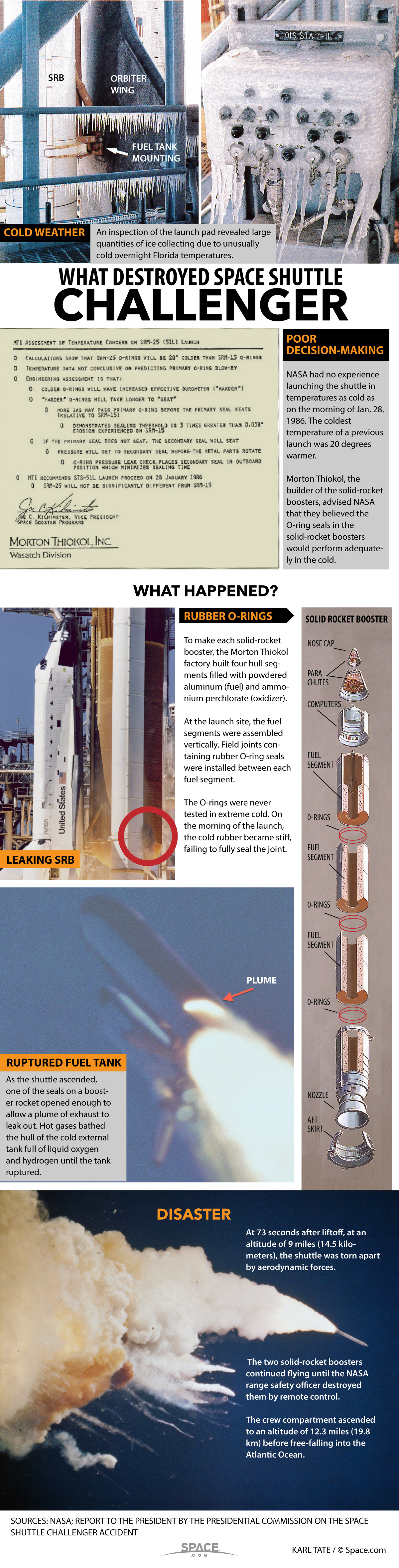

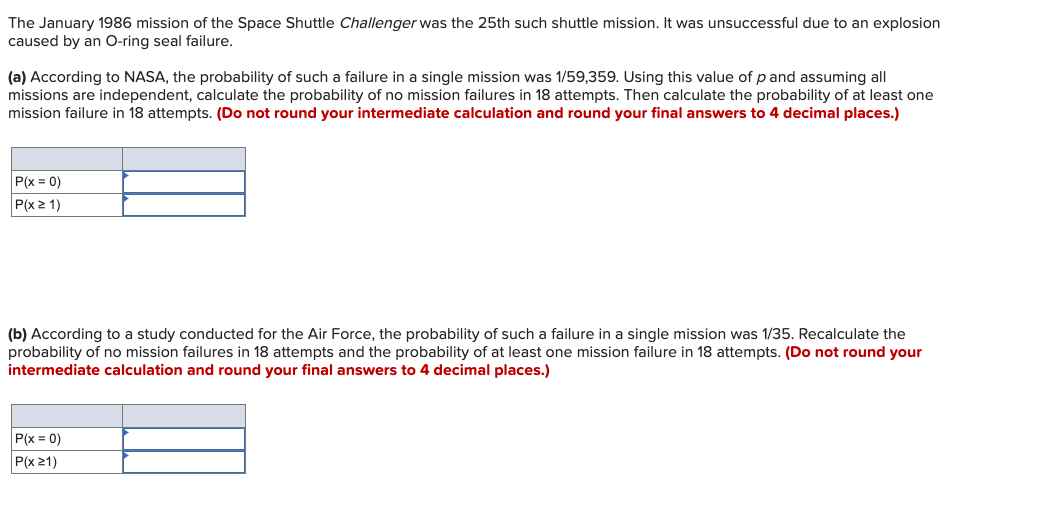

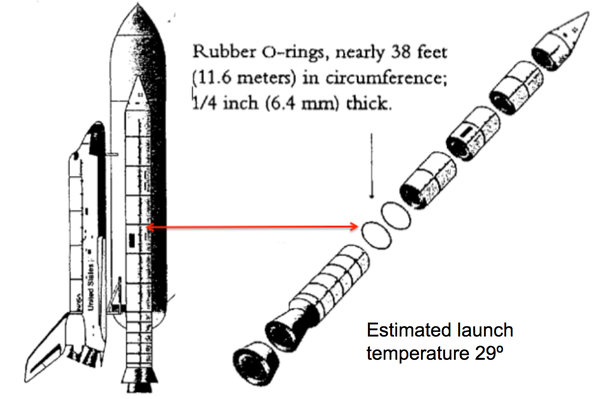

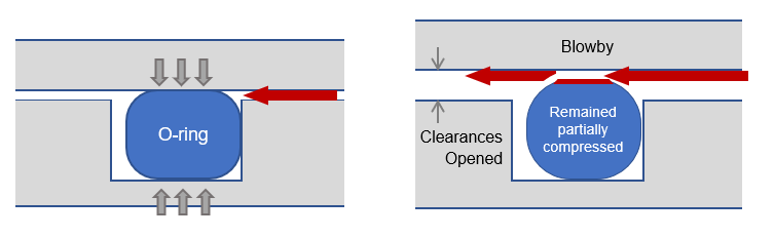

SuperPro ForUseWith Challenger (R)/Waterfall Pump Round Cut Seal Plate Pump Housing, PosiFlo II Separation Tank Lid Item ORing OEMName Pac Fab (Pentair (R))/Swimquip (TM) (StaRite (R)/Pentair (R)) OEMPart / The Orings compress and expand along with the joint to keep the seal closed Many believe that the cold weather at Kennedy Space Center on that January morning was the only weather factorThe Oring on the Challenger happened to be 12 feet in overall diameter At launch, there is high pressure inside the solid rocket boosters as the igniters light the fuel That pressure caused the pieces holding the Oring to flex slightly This relative movement between the two pieces (tang and clevis) reduced the compression on the Orings

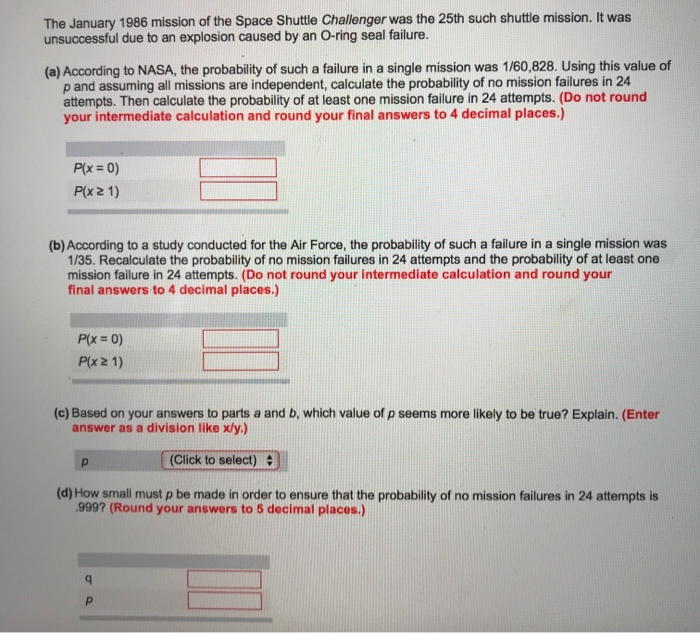

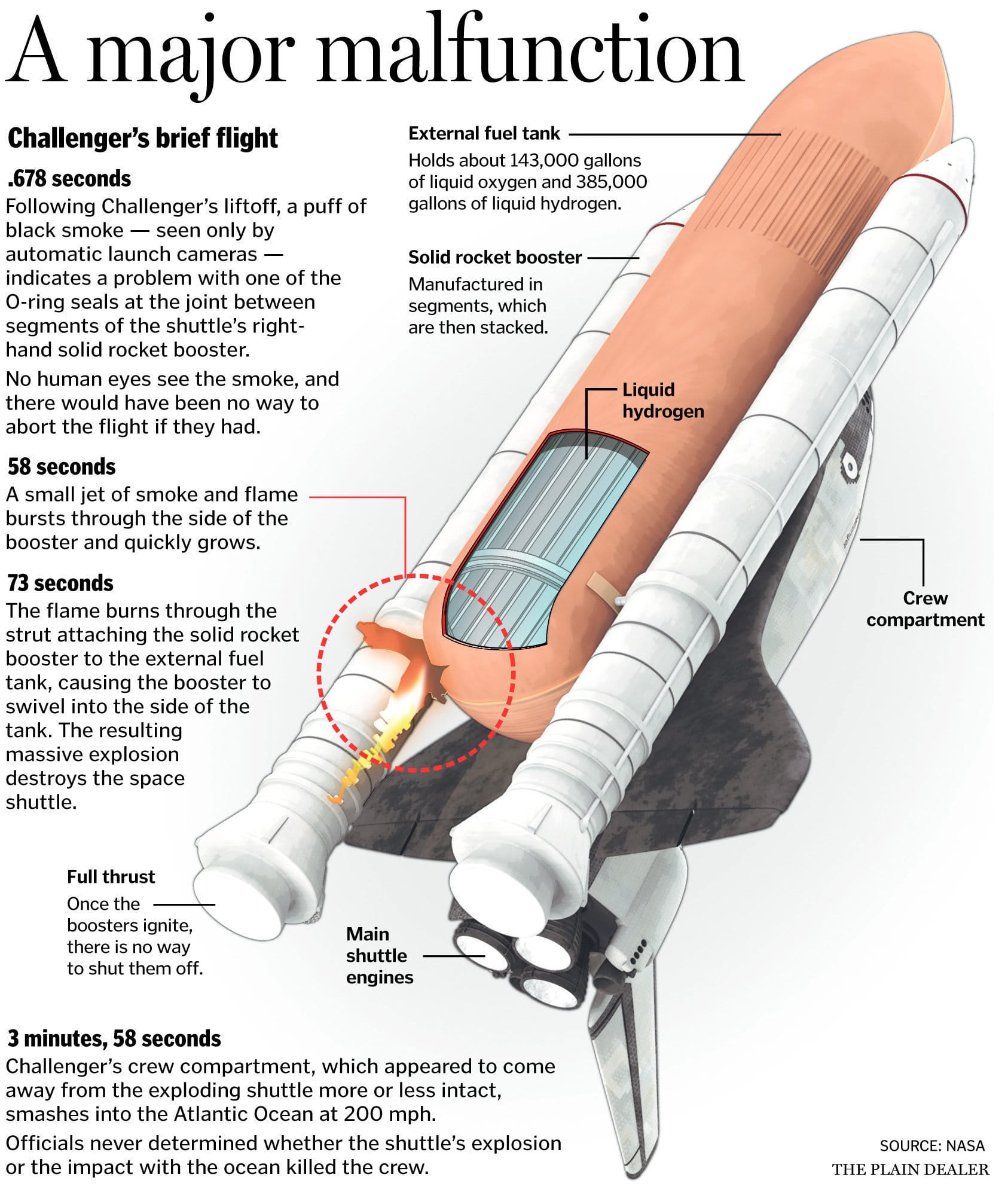

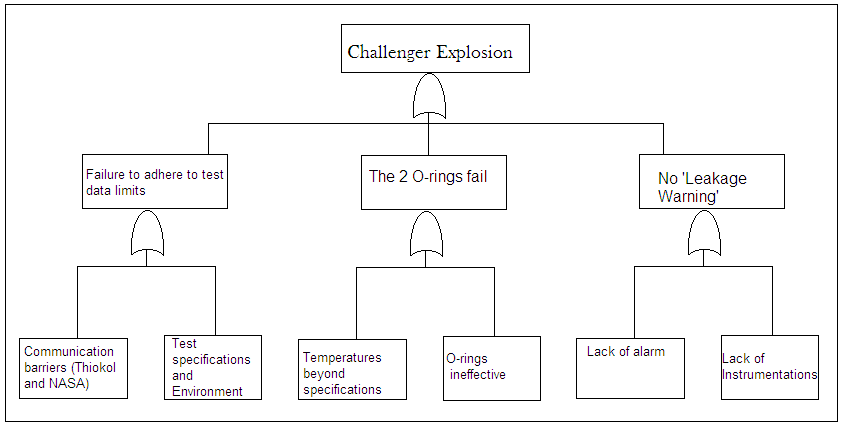

MortonThiokol discovered that both Orings (booster sealers) had malfunctioned, which led to the fuel tank blowing up The Challenger itself didn't technically "explode" but rather disintegrated from the result of the Oring malfunction The crew members' cabin remained in tact but fell to the Atlantic Ocean at approximately 0 miles per hour As most of us know, Challenger is the name for one of NASA's space shuttle orbiters that experienced a catastrophic failure on resulting in the death of all seven on board 5 astronauts, and 2 payload specialists It was determined that the catastrophic failure resulted after all five Oring seals in its right solid rocketBoisjoly's next chart showed how cold temperature would reduce the Oring squeeze making it more difficult for the Oring to extrude dynamically into the gap for proper sealing" (pgs 96 99) 11 Among everybody, there were three different temperature ranges (4850, 53, and 40 to 90 degrees) considered to be safe to launch

The Challenger accident was the result of a faulty sealing system which allowed exhaust flames from the SolidFuel Rocket Boosters (SRB) to vent directly on the external tank, rupturing the tank and causing the explosion NASA identified the failure due The Challenger was lost because one small part an Oring seal failed during a launch in cold weather The possibility of this part failing had been predicted long before, butImage The Final Crew of the Space Shuttle Challenger via Wikipedia The cause of the disaster was traced to an Oring, a circular gasket that sealed the right rocket booster This had failed due to the low temperature (31°F / 05°C) at launch time – a risk that several engineers noted, but that NASA management dismissed

Pdf Space Shuttle Case Studies Challenger And Columbia

Wholesale Bearing Seal Definition Manufacturer And Supplier Factory Gs Seal

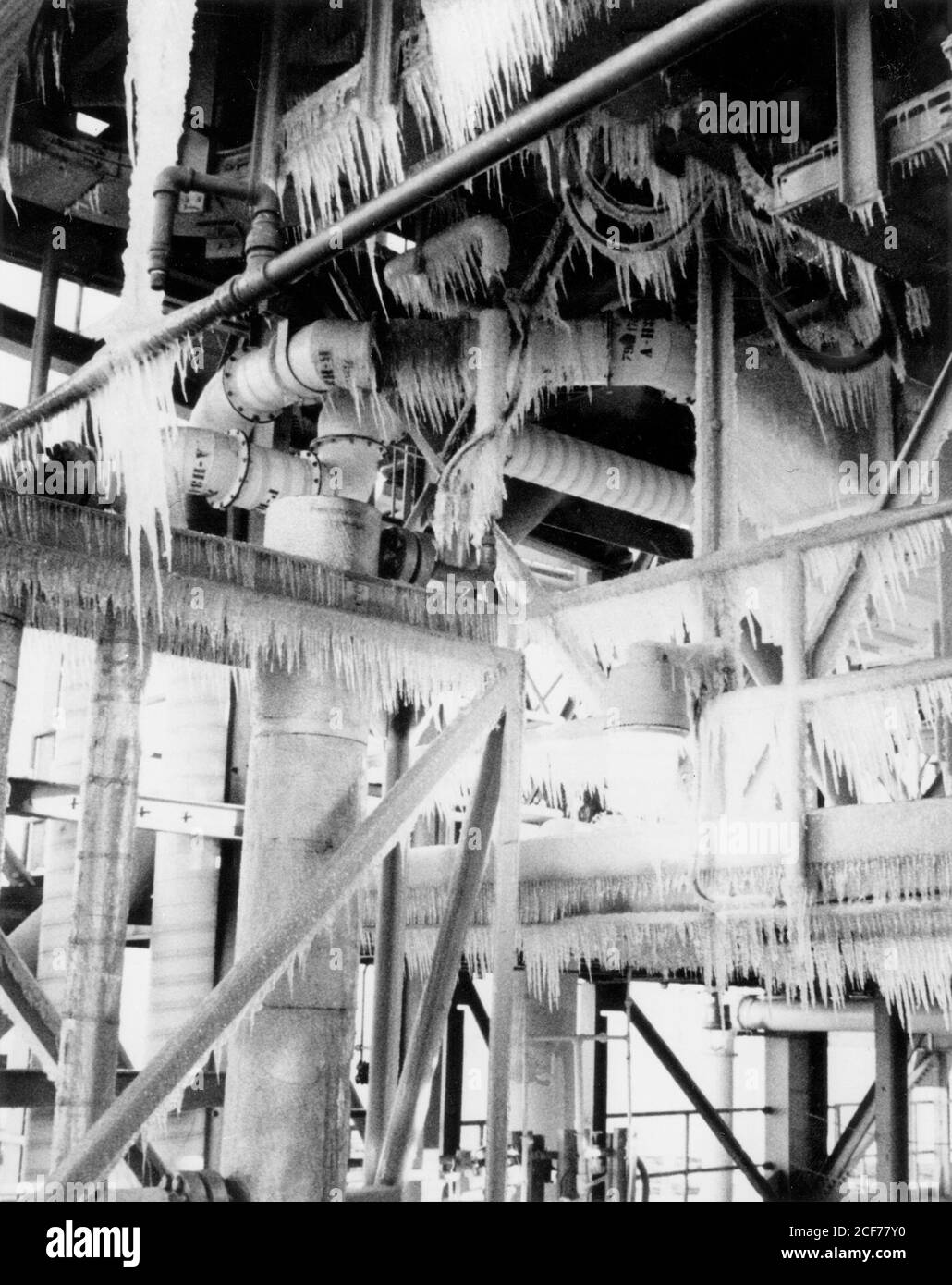

\(3092\) Fahrenheit degrees) during the launch The Orings were never tested in extreme cold On the morning of the launch, the cold rubber became stiff, failing to fully seal the joint Space Travel Danger at Every Phase (Infographic)It is a loop of elastomer with a discshaped crosssection, designed to be seated in a groove and compressed during assembly between two or more parts, creating a

Sts 51 L Recovered Debris O Ring Tracks On Right Srb Join Flickr

The Challenger Disaster Pressreader

It is a loop of elastomer with a round crosssection, designed to be seated in a groove and compressed during assembly between two or more parts, creating a seal at the interface The Oring may be used in static applications or in dynamic applications where there is relative motionThe Space Shuttle Challenger disaster was caused by the failure of an Oring seal The seal that a rubber or plastic Oring creates can either exist in a motionless joint, such as between piping, or a movable joint, such as a hydraulic cylinderHowever, movable joints often require thatRead on Challenger shortly before the explosion Source NASA On , the space shuttle Challenger exploded, killing all seven astronauts on board It was a tragic and

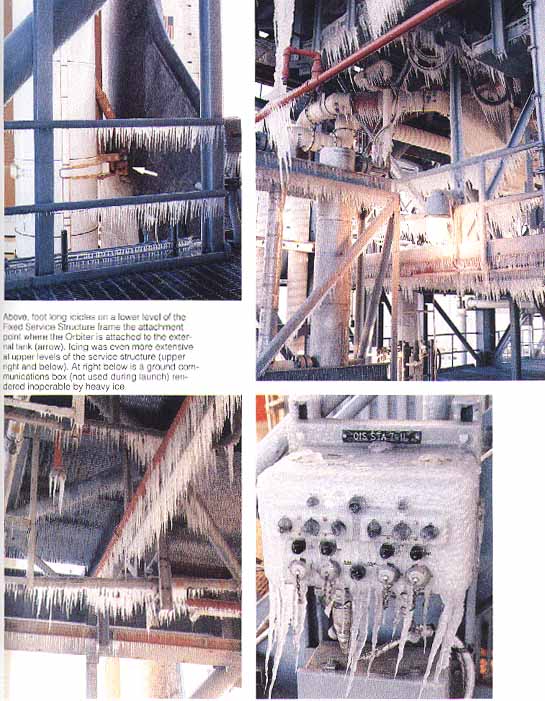

Weather S Role In The Challenger Accident The Weather Channel Articles From The Weather Channel Weather Com

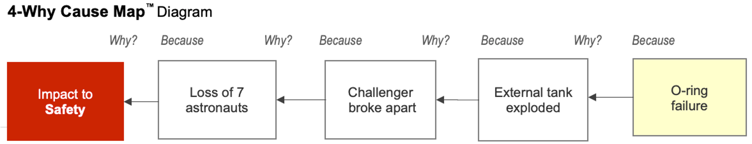

Challenger O Ring Failure Breaking One Cause Into Causes

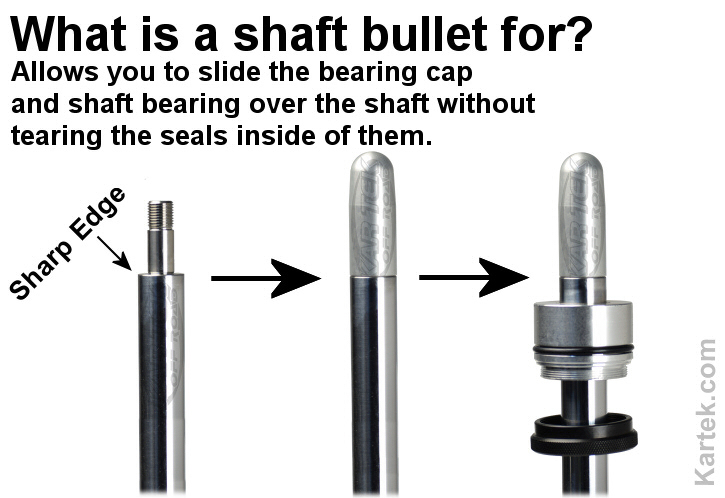

11 The sealing characteristics of the Solid Rocket Booster Orings are enhanced by timely application of motor pressure a Ideally, motor pressure should be applied to actuate the Oring and seal the joint prior to significant opening of the tangtoclevis gap ( 100 to 0 milliseconds after motor ignition) b And as we know Orings (and all other seals) work by creating positive pressure against a surface thereby preventing leaks and This was famously demonstrated physics professor Richard Feynman, when he placed a small Oring into icecold water, and subsequently showed its loss of flexibility before an investigative committee that this was the caused that at crucial needChallenger accident, the field joint was redesigned to minimize the relative joint motion caused by internal motor pressurization during ignition The Oring the Oring seal must be capable of tracking twice the maximum expected gap opening or

Space Shuttle Challenger Disaster Wikipedia

Missed Warnings The Fatal Flaws Which Doomed Challenger

The gas pressure formed by combustion inside the SRB also helps to seal the O ring This process of sealing is called Pressure Actuation Of ORing Seal As the gas goes toward the Oring, gas meets one side of the Oring and pushes the Oring from all the sides possible into the gap, thus helping to seal the joint Challenger was destroyed due to a faulty Oring seal in one of its booster rockets, allowing burning gas to escape The rubber Orings, of which there were a primary and secondary between each rocket segment, weren't supposed to be burned by the gases resulting from liftoff, but that's exactly what happened during the testing phase http//wwwFeynmanPhysicsLecturescomVarious Feynman Videos Challenger Crash ORing

An Error Occurred While Processing This Directive 7 2 Case Studies In Failure 7 2 1 Apollo 4 Three Astronauts Were Burned To Death On The Launch Pad 1967 General Electric Ge And Other Companies Were Commissioned To Develop Safety Programs

Sts 51l Explosion O Ring Seal Putty Space Shuttle Challenger 8x12 Photograph Ebay

An Oring seal had failed at launch, but the hole was quickly resealed by aluminum oxides before any flames could escape and cause an explosion Strong wind shear that began 37 seconds into flight then tore the seal back open, resulting in the catastrophic breakup The following months were anything but easy for McDonald 5 The orings were not rubber, they were silicone, which has much higher temperature resistance than rubber There was not a single oring, there were two, so if one burned through the second one was supposed to hold They were sealed upon assembly in the field with mineral paste and the joint between the two booster sections was secured withIn the Parker ORing Handbook ORD 5700 paragraph 40 says "It has been said that Orings are 'the finest static seals ever developed' Perhaps the prime reason for this is because they are almost human proof If the gland has been designed and machined properly" The disaster of Challenger mission STS51L was the result of human engineering

Challenger O Ring Gasket For Front Housing Halogen Supply

Crosman Challenger Ch09 177 Air Rifle 2x Color Coded O Ring Kit

Order Dodge Challenger A/C System ORing / Gasket Kit online today Free Same Day Store Pickup Check out free battery charging and engine diagnostic testing while you are in storeThe SRB casing and especially at the joint attachment points The failure of the Orings and putty to "seat" properly at motor ignition, caused hot exhaust gases to blow by the seals and putty During Challenger's ascent, this hot gas "blow by" ultimately cut a swath An Oring, also known as a packing, or a toric joint, is a mechanical gasket in the shape of a torus;

The Challenger Disaster Deadly Engineering Mistakes Simscale

Books You Should Read Feynman S Appendix To The Challenger Disaster Report Hackaday

Oring Seal The finger of blame pointed squarely at the boosters and, in particular, at the leaking rightside booster Initial suspicion that its range safety explosive charges had been inadvertently fired was dismissed when telemetry data revealed that no such commands were sent to either booster until both were remotely destroyed by thePac Fab () Challenger Seal Plate Pump Housing Oring Waterfall Pump SwimquipTMO Ring Seal Challenger China Manufacturers, Suppliers, Factory With sophisticated technologies and facilities, strict top quality handle, reasonable value, exceptional support and close cooperation with clients, we are devoted to furnishing the ideal worth for our clients for O Ring Seal Challenger, seal ring, valve seal, Rubber O

2

1

Challenger Disaster Blamed on ORings, Pressure to Launch *Low temperatures on launch day stiffened the rubber Orings so much that they could not maintain aAlmost everyone has heard of the Challenger space shuttle tragedy that struck, but did you know it was a failure of the lowly oring that caused the disaster? HydraPak was the sole contractor NASA used in the manufacture of the space shuttle Orings On the morning of , NASA decided to go ahead with the launch of the Challenger despite

Challenger Final Release

Challenger Explosion Thinkreliability Case Studies

The carbon seal is not suppose to be tight around the shaft, the seal to keep the water out of the hull is that little bit of tension between the carbon seal and stainless steel ring The carbon seal is stationary and the SS ring is what spins on the carbon seal when the engine is running There are 2 little O rings in your SS ring, those areHIGH FLOW CHALLENGER Housing Round Oring Replacement By LIBERTY SEALS $1078 FOR SALE!Challenger on the launchpad Arrow indicating leaking Oring on SRB After the space shuttle Challenger and its crew were destroyed in a fiery, catastrophic explosion on , NASA appointed members of the Rogers Commission to investigate the cause of the disaster

Famous Seal Disasters In History Space Shuttle Challenger Advanced Emc Technologies High Performance Polymer Seals Bearings

Engineering Failures Case Studies In Engineering

ORing Gasket Kit For PacFab Challenger Includes Oring, Pump Seal, and Lube Product information Product Dimensions 1 x 8 x 8 inches Item Weight 3 ounces Manufacturer Southeastern Accessory ASIN BEH1C Item model number Challenger Customer Engineer Roger Boisjoly examines a model of the ORings, used to bring the Space Shuttle into orbit, at a meeting of senior executives and academic representatives in Rye, New York in Their findings were worrying — the rubber Oring seals stiffened in cold weather, allowing the hot, highpressure gas inside the boosters

Space Shuttle Challenger O Ring Failure Diagram Theblaze Youtube

Fun Fact The O Ring Theory How A Space Shuttle Disaster Led To An Economic Theory Arthashastra

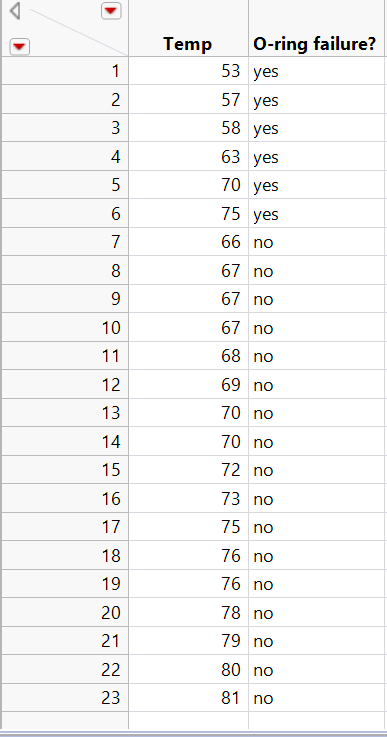

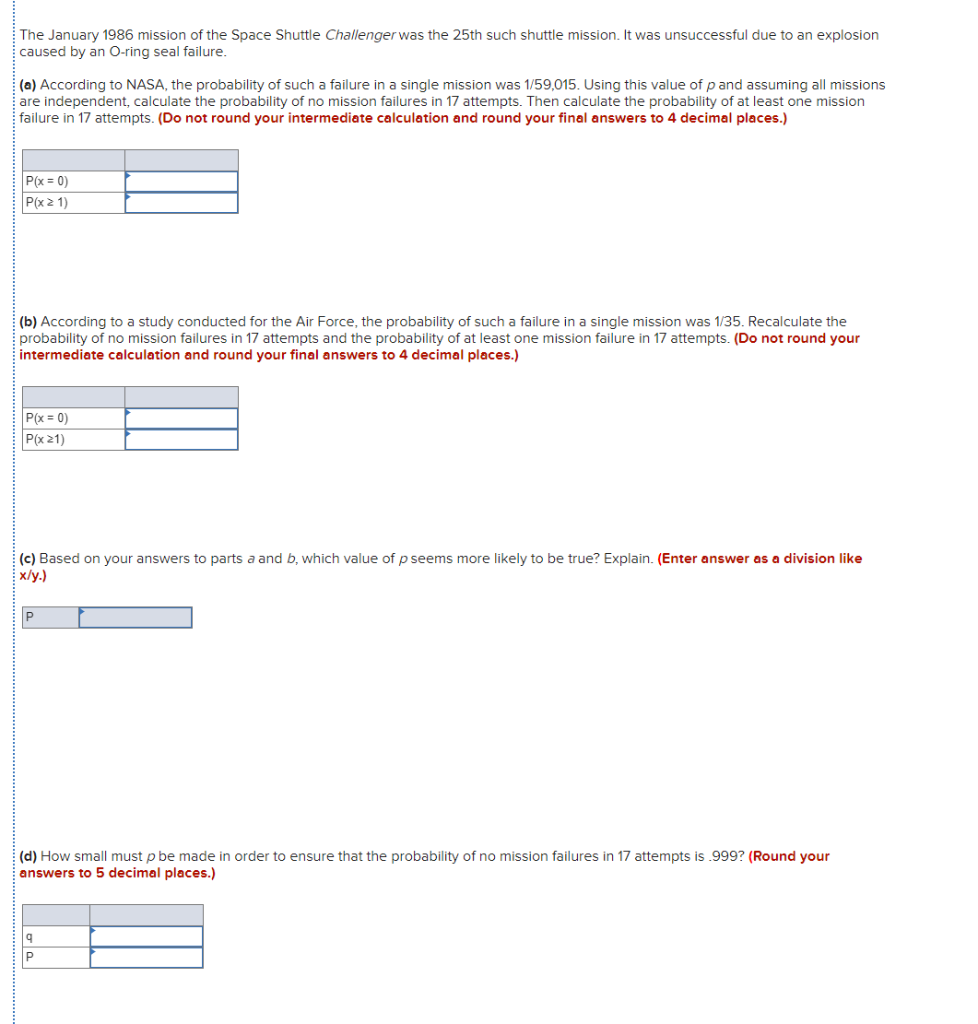

On , the left nozzle joint of STS 51B (launched April 29) was disassembled and inspected after it had been shipped back to Thiokol What Thiokol found was alarming The primary Oring seal had been compromised because it eroded 171 inches and it did not seal The secondary Oring did seal, but it had eroded 032 inchesChallenger ORing Data – Logistic Regression Background The Space Shuttle Challenger exploded 73 second after liftoff on January 28th, 1986 The main concern of engineers in launching the Challenger was the evidence that the large Orings sealing the several sections of the boosters could fail in cold temperatures10 Experiments indicate that the primary mechanism that actuates Oring sealing is the application of gas pressure to the upstream (highpressure) side of the Oring as it sits in its groove or channel a For this pressure actuation to work most effectively, a space between the Oring and its upstream channel wall should exist during

The Space Shuttle Challenger Explosion And The O Ring

2

The Rogers Commission elaborated a report (Presidential Commission on the Space Shuttle Challenger Accident 1986) with all the findings The commission determined that the disintegration began with the failure of an Oring seal in the solid rocket booster due to the unusually cold temperature (\(06\) Celsius degrees;

Space Shuttle Oringsusa

2

7 Myths About The Challenger Shuttle Disaster

2

Shaft Seal O Ring Rebuild Kit Pentair High Flow Challenger Pool Pump Pools Spas Home Garden Temakinho Co Uk

O Ring Seal An Overview Sciencedirect Topics

The Challenger Disaster Risk Management Jameson Smieja Andrew

The Space Shuttle Challenger Accident Davinder Mahal

The January 1986 Mission Of The Space Shuttle Chegg Com

The Challenger Disaster Richard Feynman

Why Did The Challenger Solid Rocket Booster Need Seals Why Were Six Joints Welded But The Last Joint Was A Non Welded Rubber Seal Design Quora

What Is An O Ring With Pictures

Nasa Engineer Who Opposed Challenger Launch Offers Personal Look At Tragedy

Xu S Sealing Theory And Rectangular O Shaped Ring Seals Science Publishing Group

6 Exercise 5 27 Methods And Applications The January Chegg Com

What Did We Learn From The Challenger Tragedy The Drive

Space Shuttle Oringsusa

Amazon Com Tiki Island Pool Express Compatible With Pentair Challenger Pool Pump Seal O Ring Kit For All Models Strainer Basket 35 5318 Patio Lawn Garden

3

2

The Space Shuttle Challenger Exploded 73 Seconds Into Flight On January 28 The Tragedy Involved Damage To O Rings Which Were Used To Seal The Ppt Video Online Download

2

2

Amazon Com Gasket Seal O Ring Rebuild Kit For Pool Pump Gasket Seal O Ring Pac Fab Challenger Pump Repair Kit 5 Garden Outdoor

Case Details Explosion Of The Space Shuttle Challenger

What Is An O Ring And How Does It Work Youtube

Badass Pool Supply O Ring Rebuild Repair Kit For Pentair Challenger High Psi High Flow And Waterfall Square Housing Gasket Buy Online In Jamaica At Jamaica Desertcart Com Productid

Crosman Challenger Ch09 O Ring Seal Kit For Sale Online Ebay

The January 1986 Mission Of The Space Shuttle Chegg Com

The Space Shuttle Challenger Disaster What Happened Infographic Space

The Challenger Disaster Deadly Engineering Mistakes Simscale

Challenger Case Study

Sts 51l And Sts 107 Challenger And Columbia A Legacy Honored Nasaspaceflight Com

Defrosting The Challenger O Rings

Weather S Role In The Challenger Accident The Weather Channel Articles From The Weather Channel Weather Com

Space Shuttle Challenger O Ring

A Statistical Analysis Of The Challenger Accident Nasa Space Space Exploration

O Ring Seal An Overview Sciencedirect Topics

Space Shuttle Challenger Disaster Wikipedia

The Challenger Shuttle Disaster What We Can Learn 30 Years Later Outdoored Com

The January 1986 Mission Of The Space Shuttle Chegg Com

Space Shuttle Challenger Disaster 1986 By Arjit Raj Rocket Science Falcon 9 And Spacex Medium

Shuttle Challenger Exploded Thirty Years Ago Today Jim On Light

Fox 2 5 Class 9 Challenger Series Rear Shock O Ring Rebuild Kits 5 8 Shaft Hose Remote Reservoir Kartek Off Road

Tedmohs Challenger Explosion Shuttle Challenger Space Shuttle Challenger

Challenger

Challenger Disaster Heeding The Ethical Lessons 30 Years On Engineering360

V4p369

Challenger O Ring Failure Breaking One Cause Into Causes

Xu S Sealing Theory And Rectangular O Shaped Ring Seals Science Publishing Group

O Ring Pump Seal Kit For Pac Fab Challenger Pool Pump Repair Kit Swimming Pool Water Pumps Patio Lawn Garden Amazon Com

Challenger

Amazon Com Truth Lies And O Rings Inside The Space Shuttle Challenger Disaster Audible Audio Edition Allan J Mcdonald James R Hansen Contributor Jonathan Yen Tantor Audio Audible Books Originals

The January 1986 Mission Of The Space Shuttle Chegg Com

Buy Tiki Island Pool Express Compatible With Challenger Seal O Ring Kit For All Models Of Challenger Pool Pump Online In Turkey B07kvr2smp

Space Shuttle Oringsusa

What Specific Type Of Rubber Were The Space Shuttle Srb O Rings Made Out Of What Changes Were Made To Them After Challenger Quora

What Happened To The Shuttle Program As A Result Of The Challenger Explosion Quora

The Challenger Disaster Deadly Engineering Mistakes Simscale

O Ring Wikipedia

Challenger Disaster Case Study Ppt Download

Challenger A Management Failure

Fits Dodge Challenger 08 Seal O Ring A C Line Pcs 10 Ebay

Nasa Engineer Who Opposed Challenger Launch Offers Personal Look At Tragedy

Seal O Ring Caterpillar Spare Part 777parts

On January 28 1986 The Space Shuttle Challenger Chegg Com

How O Ring Failure Caused Nasa S Shuttle To Blast

The January 1986 Mission Of The Space Shuttle Chegg Com

2

Lessons Learned From The Space Shuttle Challenger Disaster For The Nuclear Industry

On January 28 1986 The Space Shuttle Challenger And Her Seven Member Crew Were Lost When A Ruptured O Ring In The Right Solid Rocket Booster Caused An Explosion Soon After Launch On The

The Space Shuttle Challenger Explosion And The O Ring

Space Shuttle Challenger S Explosion Factors 6 Words Case Study Example

Lessons Learned From The Space Shuttle Challenger Disaster For The Nuclear Industry

Solnex Inc Nde Solutions

Case Details Explosion Of The Space Shuttle Challenger

0001 R S 450 1 O 419 O Ring For Challenger Seal Plate Posi Flo Ii Other Pool Equipment Parts Pool Equipment Parts

Buy Southeastern O Ring Seal Repair Rebuild Kit For Pentair Challenger High Flow High Psi Waterfall Pump Online In Indonesia B077mvgs1t

Weather A Strong Factor Behind Space Shuttle Challenger Disaster Pioneers Of Aviation

The Space Shuttle Challenger Explosion And The O Ring

0 件のコメント:

コメントを投稿